yerden ısıtma straforu Teknofer

TEKNOFER Foil floor heating styrofoam prices systems underfloor heating materials

NOTE: We strongly recommend you to watch our video below about underfloor heating styrofoam prices and mistakes made in underfloor heating systems!

Teknofer floor heating styrofoam is one of the floor heating materials that are candidates to become indispensable with its price and quality. Thanks to the male and female channels on the edges of the styrofoam panel, it will not be difficult to fix it to the floor as in flat panels, and a great saving will be made in labor and time. For example, you can contact us for the cost of 100 m2 floor heating.

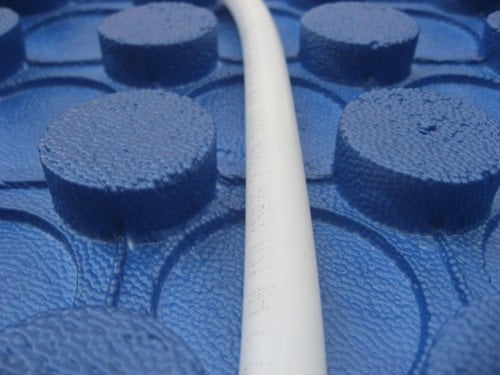

As is known, the heat received from underfloor heating pipes is closely related to the distance between the pipes. Therefore, even though flat styrofoam is used in underfloor heating systems, the pipes will come out of their places as they are stepped on due to the soft material structure and will come closer and farther away in some places. This will negatively affect the surface comfort temperature as it affects the heat received from each meter of the pipe. Teknofer underfloor heating styrofoam will provide much more homogeneous heating by facilitating the fixing of underfloor heating pipes thanks to the mushroom structures on it.

As is known, the heat received from underfloor heating pipes is closely related to the distance between the pipes. Therefore, even though flat styrofoam is used in underfloor heating systems, the pipes will come out of their places as they are stepped on due to the soft material structure and will come closer and farther away in some places. This will negatively affect the surface comfort temperature as it affects the heat received from each meter of the pipe. Teknofer underfloor heating styrofoam will provide much more homogeneous heating by facilitating the fixing of underfloor heating pipes thanks to the mushroom structures on it.Teknofer Underfloor Heating Styrofoam Panel Features

Raw Material: Eps/Polystyrene Foam

Density: 26 Density (26 kg/ m3 )

Thermal Conductivity VALUE: 0.036 W/mK

Cover: Polystyrene and polyethylene mixture foil

Dimensions: 720 mm X 720 mm = 0.51 m2 / Piece

10 Pieces = 1 Package : 1 Package = 5.1 m 2

Base Thickness: 20 mm

Set Mushroom Thickness: 20 mm

Surface Insulation Thickness: 30 mm Total thickness 40 mm

Modulation Range between Sets: 60 mm - 120 mm - 180 mm - 240 mm

The flat styrofoam used in classic floor heating styrofoam systems should be fixed to the floor with dowels. Otherwise, when the floor heating pipes are laid, they will fold and lift the floor heating styrofoam with them. The dowel holes that need to be drilled into the base concrete to fix the floor heating styrofoam to the base are quite a laborious process. If you use Teknofer panels in your applications, you will have a much simpler installation opportunity by overlapping the male and female channels on the edges of our panels. This feature will provide you with great advantages in terms of labor and time in today's world where speed is directly proportional to profit.

The flat styrofoam used in classic floor heating styrofoam systems should be fixed to the floor with dowels. Otherwise, when the floor heating pipes are laid, they will fold and lift the floor heating styrofoam with them. The dowel holes that need to be drilled into the base concrete to fix the floor heating styrofoam to the base are quite a laborious process. If you use Teknofer panels in your applications, you will have a much simpler installation opportunity by overlapping the male and female channels on the edges of our panels. This feature will provide you with great advantages in terms of labor and time in today's world where speed is directly proportional to profit.  The cork layers on Teknofer Underfloor Heating Styrofoam are among its most important features. The heat you receive from each meter of the pipes used in underfloor heating applications will decrease as the pipe intervals get closer to each other and increase as they get further away. Therefore, although the installation team that will perform the application uses equipment such as sheet clips in the use of flat styrofoam, the pipes get loose while walking on it due to the soft structure of the styrofoam and get very close to each other in some places and move away in some places, just like a snake. This causes inhomogeneous temperature distributions. The cork structure on it does not allow the pipe intervals to deteriorate and the temperature distribution to become unbalanced by getting loose while compressing the pipes.

The cork layers on Teknofer Underfloor Heating Styrofoam are among its most important features. The heat you receive from each meter of the pipes used in underfloor heating applications will decrease as the pipe intervals get closer to each other and increase as they get further away. Therefore, although the installation team that will perform the application uses equipment such as sheet clips in the use of flat styrofoam, the pipes get loose while walking on it due to the soft structure of the styrofoam and get very close to each other in some places and move away in some places, just like a snake. This causes inhomogeneous temperature distributions. The cork structure on it does not allow the pipe intervals to deteriorate and the temperature distribution to become unbalanced by getting loose while compressing the pipes. Perhaps the most important feature that makes Teknofer Underfloor Heating Styrofoam stand out from its competitors and make it the most efficient underfloor heating panel is that the panels are covered with a special protective foil layer.

Perhaps the most important feature that makes Teknofer Underfloor Heating Styrofoam stand out from its competitors and make it the most efficient underfloor heating panel is that the panels are covered with a special protective foil layer.