Electrostatic Filter Prices and features

0 (332) 234 24 99

Electrostatic Filters are considered as an option in odor trap systems. Their working principles are as follows; Electrostatic filters work on the principle of capturing charged particles in the air passing between them by the electrostatic attraction force by utilizing the high voltage field created between the plates. Their particle holding capacity is quite high. The dirty air drawn by the fan passes through the washable metal pre-filter in itself. This filter holds coarse dust and oil particles. Then, the oil, smoke and soot in the air coming to the electrostatic filter, which operates according to the principle of ionizing particles, is negatively charged with the high voltage charge. While the negatively charged dirty air passes through the positively charged area in the second stage, the oil, smoke and soot particles in the air are strongly attracted by the collector plates and adhered to the filter surface.

Electrostatic Filters are considered as an option in odor trap systems. Their working principles are as follows; Electrostatic filters work on the principle of capturing charged particles in the air passing between them by the electrostatic attraction force by utilizing the high voltage field created between the plates. Their particle holding capacity is quite high. The dirty air drawn by the fan passes through the washable metal pre-filter in itself. This filter holds coarse dust and oil particles. Then, the oil, smoke and soot in the air coming to the electrostatic filter, which operates according to the principle of ionizing particles, is negatively charged with the high voltage charge. While the negatively charged dirty air passes through the positively charged area in the second stage, the oil, smoke and soot particles in the air are strongly attracted by the collector plates and adhered to the filter surface.

The high voltage units in our air cleaning plants are specially designed. These units operate with 220 Volts. They produce high voltage between 7,000-15,000 volts at 300 Watts and above. Thanks to the specially designed high voltage units, our electrostatic filters provide very strong filtration.

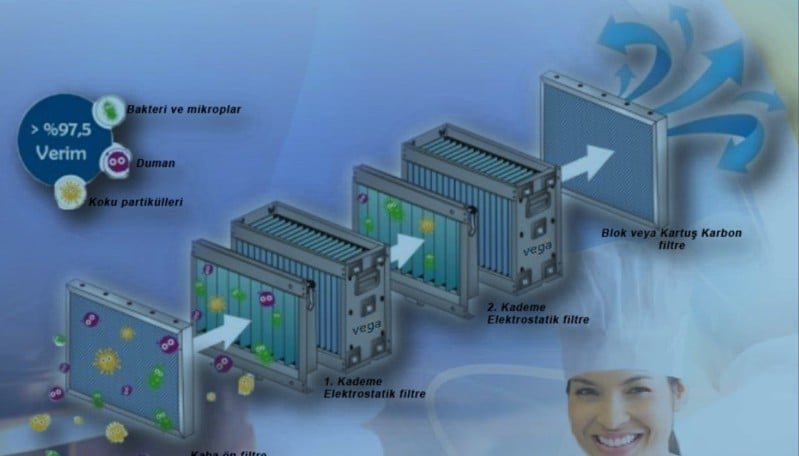

The anode and cathode fins of the filters are made of aluminum material, while the chassis and cabin are made of galvanized material. In order to have high strength, all joints are connected with tig welding. They have a structure that does not tear, puncture, warp, break or disintegrate. You do not need to replace our filters with a new one unless they are exposed to a physical effect. When they get dirty, you can wash them with oil remover and hot water and use them over and over again. Our electrostatic filters can be manufactured in two stages. Electrostatic filters can be used alone or in odor-trapping units.

How Does an Electrostatic Filter Work?

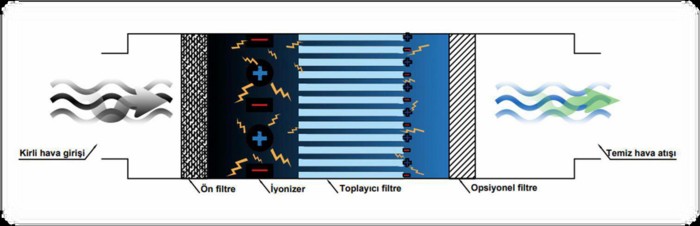

An electrostatic filter is made up of various components designed to filter smoke and odor particles . The contaminated air is passed through three different stages to ensure complete separation. The diagram below shows how an electrostatic filter works.

Dirty air first passes through the coarse pre-filter. In this way, large particles are caught in the porous structure and are held. The remaining pollutants with a size of 10 to 0.1 microns are charged with a negative electric charge in the ionizer charger. Negatively charged particles passing through the collector cell are attracted and collected by the positively charged plates. These particles, which accumulate over time, are filtered from the plates and stored in the oil pan.

TF series ecological products consist of a pre-coarse filter and a single-stage electrostatic filter. There is no active suction fan in the TF series . It can be easily integrated into existing ventilation systems and allows for subsequent changes. Since the TF series has small dimensions, it can be used by hanging it on the ceiling or ventilation duct. In this way, the space problem for device installation is eliminated.

Electrostatic Filter Usage Areas

- In restaurants

- In hotels

- In cafes

- In Industrial Kitchens

- At barbecues

Benefits of Using Electrostatic Filters

- Minimum fire risk

- Minimum maintenance and consumable costs

- Minimum environmental pollution

- Minimum energy consumption

- Minimum loss of efficiency

Electrostatic Filter Internal Parts

Electrostatic Filter Stages

Electrostatic filters are devices that are specially produced according to the work done, hood size, area, human density, location and many other factors . They are supported by many filtering systems in order to meet the need .

The main goal of these devices , which increase in size gradually and aim for sufficiency in terms of odor and smoke performance, is to increase the percolation rate as much as possible.

It is produced as single stage - double stage - three stage and above , and the design is specially designed in the quantities of both electrostatic filters and other filters. In order to meet the need according to the location and capacity, we also have completely special design productions in addition to the normal molds we produce . The aim here is to meet the needs of the user at the maximum level and to provide permanent solutions. Along with the special studies made in capacity and design, we also aim to make our customers as happy as possible in terms of color .

We also meet the needs of our customers in the field of ventilation with our productions where the desired filters are in a single cabin , except for the fan upon request, only according to the need and demand . A simple "Electrostatic filter + Cartridge carbon filter" duo, which is produced as a single stage and has a wide area of use , can do a lot of work, and we can also state that it works with high performance in the right area and with the right capacity .

Package Type Electrostatic Filters

Package type electrostatic filters are devices that we specially design and produce to meet basic filtering needs, save space and with the "PLUG-AND-PLAY" logic. While its system and use are simple, it is highly efficient and more efficient in terms of performance than models that are combined piece by piece . The reason for this is that the air flow is carefully calculated by taking into account the design of the device, the arrangement of the internal parts and the dimensions of the cabin, and the selection of the fan to be used inside the device is made according to these factors.

In package electrostatic filters, as we work in the field of import and export, the dimensions of the device have been kept as small as possible without compromising performance and efficiency, taking into account the shipping costs for the buyer, and the volume-weight balance has been calculated completely considering the buyer's interests.

Examine the image below to see the practicality of use and installation in package type electrostatics . The connection point of the duct line to the device is of vital importance. It is one of the points that should be taken into consideration in order to ensure that the air velocity decreases or reaches the desired level and the distribution is equal . Otherwise, incorrect connections negatively affect the performance of the device and reduce the filtration rate . Many factors such as duct length, diameter - width, elbows and so on should be calculated in detail and these should be taken into consideration in determining the device capacity .

Central Type Electrostatic Filters

Central Type Electrostatic Filters

This powerful design, which we produce for large projects where the most intense odor - smoke concept is experienced and where a classic electrostatic filter is insufficient, is a Central Type Electrostatic Filter with a powerful design resistant to the external environment, equipped with filters placed inside that filter the air flow at the highest level.

This device, which includes all its components, is produced as a single piece and with the PLUG-AND-PLAY logic. It can be used immediately after the assembly connection . Some factors come to the fore in device selection.

In the table below , we wanted to show some details that we think will help you in your selection to meet your needs. Depending on the details of the work done and the place, you can contact us and ask for support.